Sonocon BL Portable Ultrasonic Flaw Detector

Sonocon BL Portable Ultrasonic Flaw Detector

Sonocon BL belongs to the latest generation of portable UT instruments. Using high-end electronics and having the richest set of modes and software features, it can solve any task that can be sold with portable UT.

Overview

-

SOLID ONE with a really BIG SCREEN

Sonocon BL has an ergonomic shock-resistant ABS plastic case with additional rubber pads and is designed for use in field as well as in industrial conditions. The Sonocon BL has a 7.2” huge high-resolution display. In combination with well-designed interface, this enables observing the A-Scan without strain even distantly.

-

Versatile

Due to its case design and a 4-position folding handle, Sonocon BL can be comfortably placed on the table, pipe or another test object and even suspended. It also can be fixed on the inspector’s chest for better mobility.

-

Powerful and Multifunctional

Sonocon BL is a digital UT tester combining 3 devices in 1:

- Flaw detector,

- A-Scan thickness gauge,

- Corrosion monitor

This is realized with switchable software. In “UT” version Sonocon B grants all functions of a powerful ultrasonic flaw detection necessary for its setup, defect search and their advanced evaluation.

-

Usage in harsh environments

The instrument case carries an IP65 rating. The operation temperature ranges from –30°C to +50 °C (-22°F to 122°F). The flaw detector is resistant to ionizing radiation impact and is meant for operation under high humidity conditions.

-

Easy to use

Sonocon BL is highly user friendly. Its interface philosophy can be stated as “Don’t browse menus, just push a button!”. All most frequently used functions are placed on its keyboard making them accessible in a single or a couple of button presses. This makes setup and evaluation procedures several times faster. A variety of built in auto calibration procedures allow performing fast and easy calibration with straight beam, angle beam and Rayleigh wave probes on standards or even a testing object.

To help new users to get used to its interface, Sonocon BL offers a number of options:

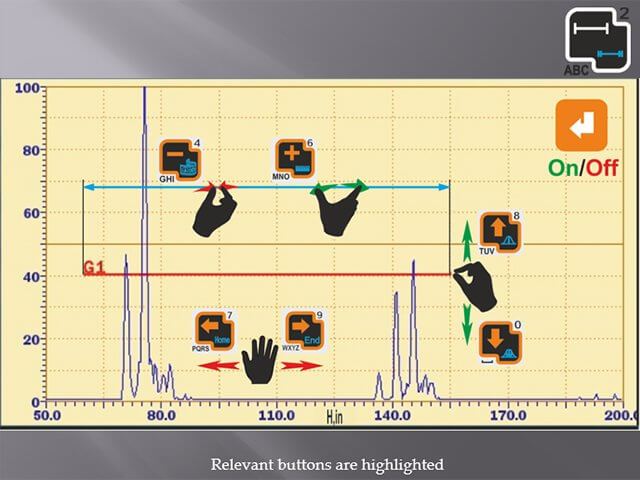

- Context backlight: in modes where a group of buttons considered to be used all relevant buttons are highlighted.

- Menu items hints: All not trivial menu items show descriptions when activated (changed).

-

Menu presets: User can choose one of 3 menu system presets:

- Full: contains all menus in 2 pages granting access to all UT instrument functions;

- Simple1 & Simple 2: contain in one page all basic functions, grouped in a couple of menus. Also gives possibility to add any 3 or 4 extra menus from a Full Menu list.

The Sonocon is available in two versions now:

General Features

Performance

Dual modes pulser

Sonocon BL implies two pulser modes: Spike and Square Wave (SWP). This and also a damping feature allow controlling echo shape, length and amplitude in wide ranges.

Waveform Averaging

This function allows to average A-Scan from ×2 to ×64. This greatly raises Signal / Noise ratio allowing comfortably working at even very high gain and making measurements more precise.

Quick and comfortable operation

Direct A-Scan and Gates control

After pushing just a single button operator can intuitively control A-Scan and gates.

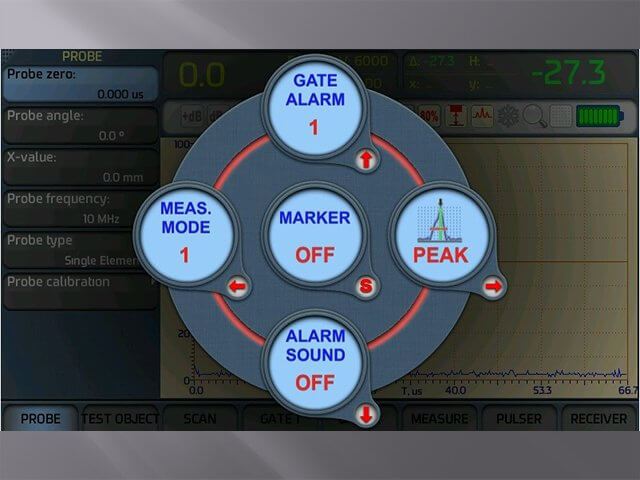

The QAM button grants access to a queue of circular menus which allow quick change of measurement and alarm parameters.

“UT” version

Indications search and evaluation aids

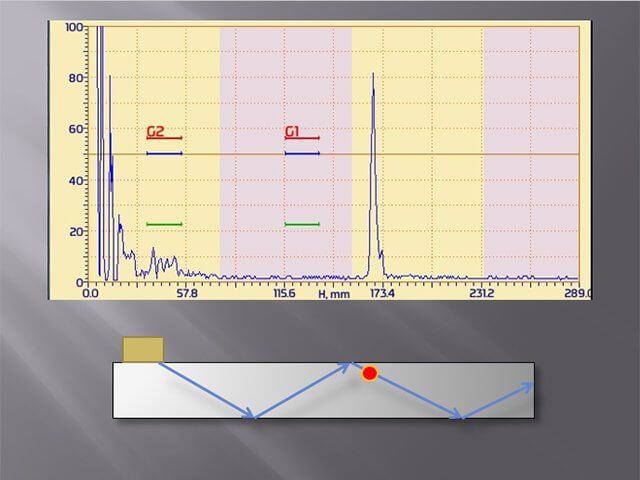

“Legs marking” mode

“Legs marking” mode changes A-Scan background marking A-Scan parts corresponding to downgoing legs in yellow and to upgoing legs – in rose. This helps to visually estimate depth of the reflector (defect) which caused an indication.

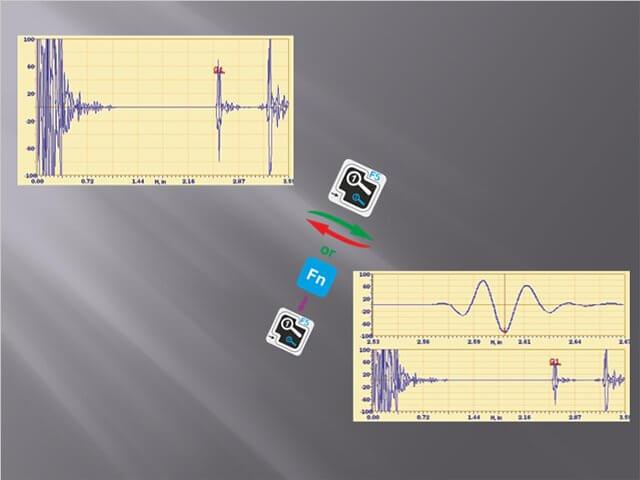

“Smart zoom” mode

In this mode both zoomed A-Scan (from one of two gates) and a full 0 unzoomed A-Scan are displayed. This prevents operator from losing an off gate indication.

“Estimate” mode

“Estimate” mode is very useful for evaluation of “hard to catch” indications. It also makes evaluation of usual indications much quicker. When this mode is on operator needs only to make a blind scanning of the area of interest and flaw detector will monitor all echoes in the 1st gate, looks for the best one (according to the amplitude), auto adjust gain to put that echo to the evaluation level and freeze it. The “best” indication can be then evaluated and saved for reporting if needed. After the “Estimate” mode is off the scanning gain is automatically retrieved.

Flaws evaluation systems

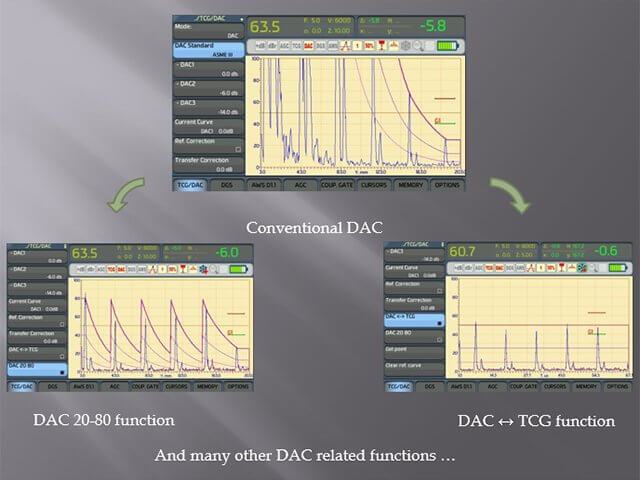

DAC system

Built-in DAC system allows to build DAC curves according to the following codes: ASME (single curve and 3 curves), EN 1712, EN 1713, EN1714, JIS Z3060, GB 11345, GB 4730. User presets are also available. Base curve can contain up to 128 points. There can be built up to 6 additional curves. Besides all standard functions used in any DAC system Sonocon BL offers such advanced functions like “20-80” function, DAC ↔ TCG conversion function, etc.

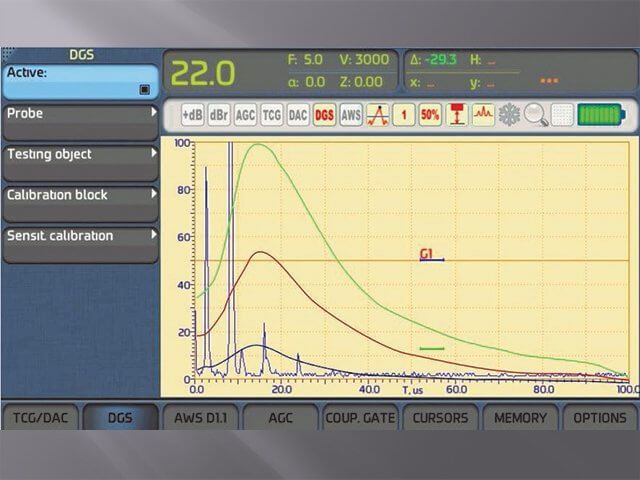

DGS (AVG) system

DGS system allows to build up to 3 DGS curves for given equivalent diameters (area) for straight beam and angle beam single element transducers. It also gives direct readings of De and / or Se for gated indication.

AWS (D rating) system

Sonocon BL also implies automated calculation of D-rating according to American Welding Society Structural Welding Code section D1.1, D1.3.

“Thickness gauge +” version

Setup automation

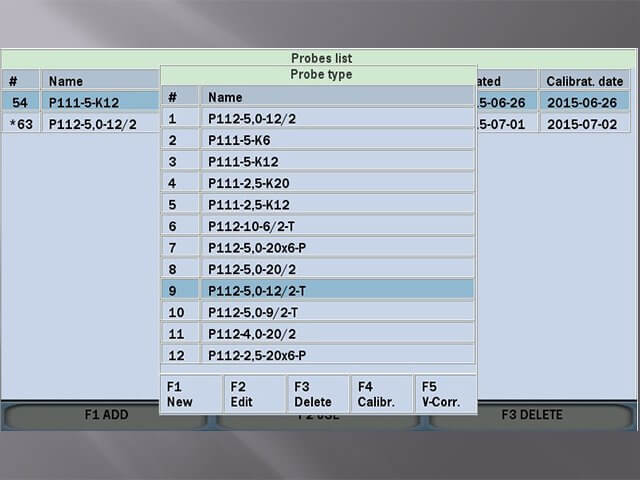

Probes library

To set up the chosen probes parameters now it is enough to choose corresponding item from the Probes library and all related settings will be loaded autamtically.

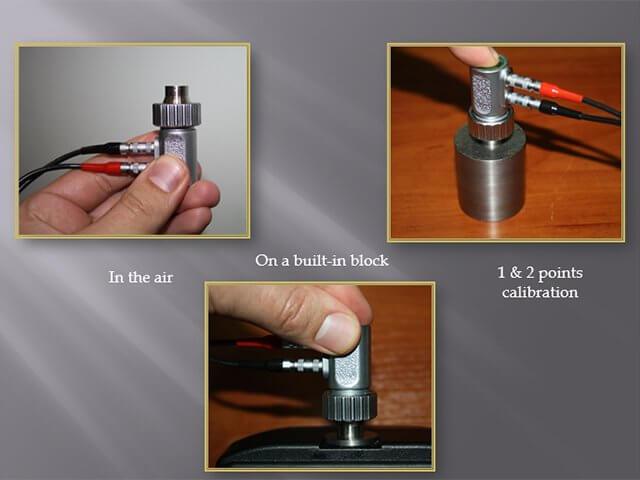

Automatic calibration

Sonocon BL offers a variety of automated calibration procedures: in the air, on a built-n calibration block and classic single and dual points calibration.

Results storage and processing

Structured files

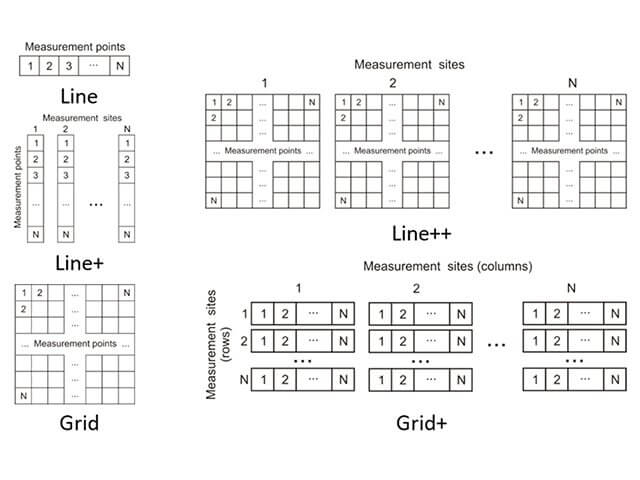

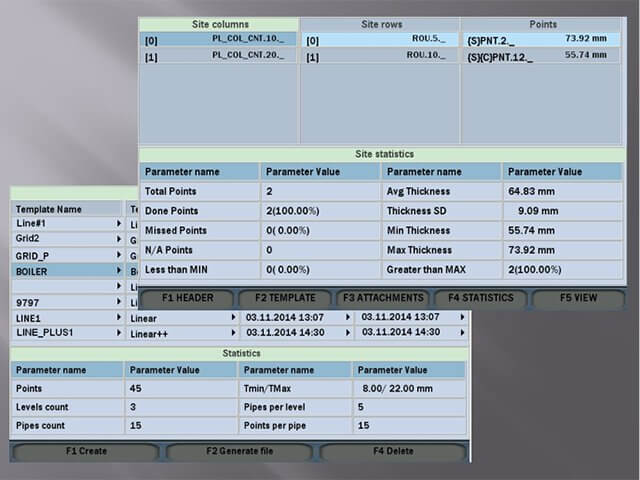

One of the most important and difficult task in thickness measurement at large objects is to correctly organize measurement results in a way to facilitate their analysis. Using Sonocon BL operator can choose one of several templates corresponding to almost any type of testing objects:

- “Line” (1D) is ideal for tank truck, small diameter pipes, etc.

- “Line+” (2D) is used for a linear group of “Line” objects, for section by section large diameter pipes thickness measurement, etc.

- “Grid” (2D) is used for testing of large semi planar object like ship’s hull, storage tanks, large diameters fluid conductors, etc.

- “Line++” (3D) is used for testing of a 2D group of “Line” objects.

- “Grid+” (3D) is used for a linear group of “Grid” objects.

- “Boiler” (3D) organizes measurement points on pipes and pipes on levels.

Measurements statistics on the go

Sonocon BL allows not only to review organized measurement data, but also to analyze them, providing statistics for the whole file and each of measurement sites.

Corrosion monitoring

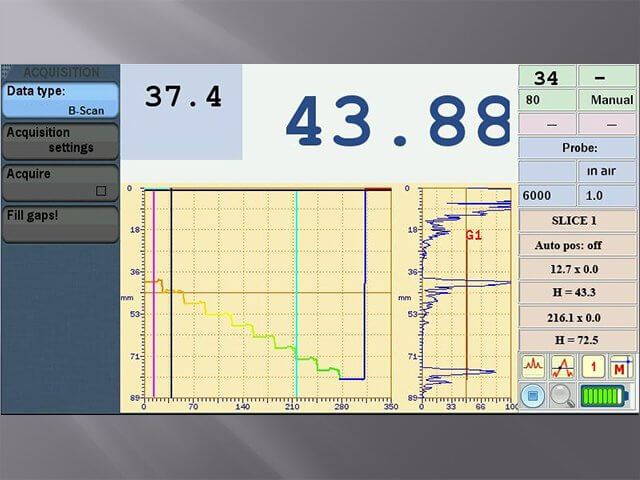

Thickness B-Scans

Thickness B-Scan – a slice of the object by the ultrasonic beam are easy to acquire with any 1D scanner with encoder. It shows a back wall profile, which is useful to estimate corrosion type.

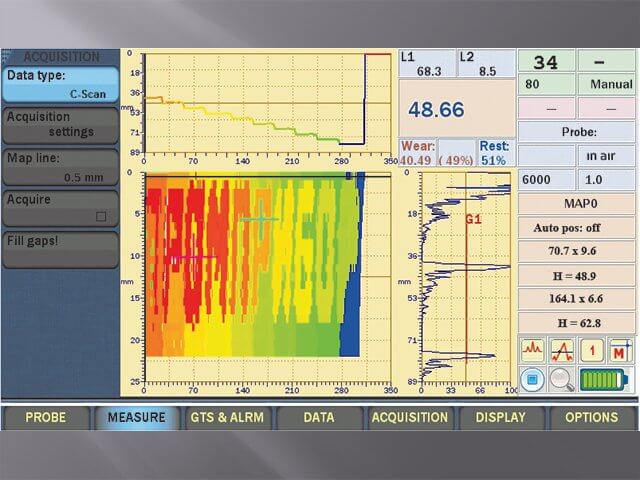

Thickness C-Scans

Thickness C-Scans are acquired with a 2D scanner or a series of linear scans with 1D scanner and are used for corrosion mapping.

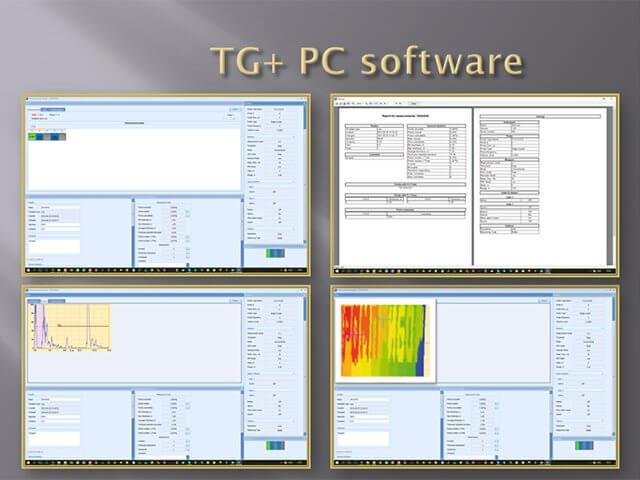

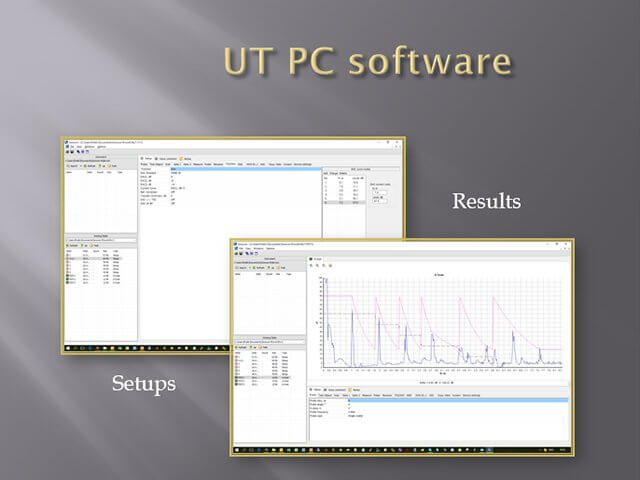

PC Software

Sonocon BL goes with PC software package corresponding to the inner software – UT, Thickness or both.

PC software is used for organization of instrument setups and testing results, their analysis and reporting.

Thickness gauge +:

UT:

Specification

Sonocon BL General and "UT" Version

| Display | |

| Size | Sonocon BL: 7.2” |

| Resolution | 800×480 |

| Connectors | |

| Probe connectors | 2 × BNC or 2 × LEMO-1 or 2 × LEMO-00 |

| Analog output | Alarm |

| USB1 | Type A |

| LAN | ✔ |

| Pulser | |

| Types | Spike + Square Wave (SWP) |

| Voltage (SWP) | 50 V, 100 V, 150 V, 200 V, 250 V, 300 V, 400 V |

| Energy (SWP) | 20 ns to 1000ns with 10 ns step Manual & Auto modes |

| Voltage (Spike) | Low: 50 V, High: 300 V |

| Damping | ✔ |

| PRF modes | Comfort, Low, Medium, High, Manual |

| PRF | from 15 to 6000 Hz |

| Phantoms control | 3 modes |

| Receiver | |

| Range (at steel longitudinal wave) | 8 000 mm (314 in) |

| Gain | 0 to110 dB, with 0.1 dB step |

| Max signal input | 20 V p-p |

| Bandwidth | 0.2 MHz - 27 MHz |

| Filters | 0.2-27 MHz, 0.2-10 MHz, 2.0-21.5 MHz, 8.0-26.5 MHz, 0.5-4 MHz, 0.2-1.2 MHz, 1.5-8.5 MHz, 5-15 MHz, 0.4 MHz, 0.5 MHz, 1 MHz, 1.25 MHz, 2 MHz, 2.25 MHz, 2.5 MHz, 3.5 MHz, 4 MHz, 5 MHz, 7.5 MHz, 10 MHz, 15 MHz, 20 MHz |

| Filters set choice | ✔ |

| Rectification | RF, FW, Pos. HW, Neg. HW |

| TCG (TVG) | 110 dB; 110 dB/μs slope |

| Signal Average | OFF / 2x / 4x / 8x / 16x / 32x / 64x |

| Reject (cutoff) | 0-80% FSH |

| Measurement | |

| Number of gates | 2 |

| Number of cursors | 2 |

| Modes | 1, 2, C1, C2, 1-2, 1-C1, 1-C2, 2-C1, 2-C2, C1-C2 |

| TOF Modes | Peak, Edge (Flank) |

| Amplitude measurement | up to 200% FSH |

| Units | mm / in / us |

| Output fields | 5 |

| Alarm | |

| Number of gates | 2 |

| Number of levels | 3 |

| Flaws evaluation | |

| AWS | ✔ |

| DGS (AVG) | ✔ |

| DAC | ✔ |

| DAC: Number of points | 128 |

| DAC codes | ASME & ASME III, EN 1712, EN 1713, EN1714, JIS Z3060, GB11345, GB 4730 |

| Custom DAC curves | up to 6 |

| DAC 20-80 | ✔ |

| DAC & TCG | ✔ |

| Memory | |

| Setups | ✔ |

| Datasets (with A-Scans) | ✔ |

| Capacity | 2 GB (up to 64 GB) |

| PC software | ✔ |

| Other Features | |

| Coupling control | ✔ |

| AGC | independent for both gates |

| Quick calibration | ✔ |

| Quick estimate (Best signal catch) | ✔ |

| Auto XX % (50% or 80%) | ✔ |

| Reference gain | ✔ |

| Peak hold (collect, peak memory) | ✔ |

| Signals compare | ✔ |

| Smart zoom | ✔ |

| Choice of menu systems | Full Simple 1 Simple 2 |

| Keyboard backlight | ✔ |

| Smart (Context) keyboard backlight | ✔ |

| Number of keyboard shortcuts2 | 41 |

| Physical | |

| Dimensions | Sonocon BL: 10×6.1×3.1"(256×156×80 mm3) |

| Weight incl. battery | Sonocon BL: 5.3 lbs (2.4 kg) |

| Operating temp. range | -30°C to 50°C (-22°F to 122°F) |

| Dust & water protection | IP65 |

| Battery life | 8 h |

| Replaceable battery | ✔ |

Sonocon BL "Thickness Guage +" Version

| Pulser | |

| Type | Square Wave (SWP) |

| Autofit of the pulser parameters to the chosen probe | Voltage, Energy, Damping |

| Measurement frequency (readings refresh rate) | 1 to 100 Hz |

| PRF mode | Auto (Calculated from set readings refresh rate, accounting for averaging rate) |

| Receiver | |

| Range (at steel longitudinal wave) | 8 000 mm (314 in) |

| AGC | Individual to reach at 2 gates |

| AGC Modes | OFF / Edge / Peak |

| AGC Max Gain Modes | High, Medium, Low, Manual, Off |

| Auto filters choice (according to the probe type) | ✔ |

| Measurement | |

| Sound velocities range | 250 to 16000 m/s (.01 to .629 in/µs) |

| Measurement range | 0.4 to 16 000 mm (.016 to .629 in) |

| Readings resolution | 0.01 / 0.1 / 1 mm (0.001 / 0.01 / 0.1 in) |

| Number of gates | 2 |

| Modes | 1, 1-2 |

| TOF Modes | Edge, Edge Zero Crossing |

| Units | mm / in |

| Min & Max capture mode | ✔ |

| Differential mode | ✔ |

| % of wear mode | ✔ |

| Temperature compensation | ✔ |

Acquisition of a:

|

✔ ✔ |

Measurements on the previously acquired:

|

✔ ✔ |

| Alarm & Display | |

| Alarm types | Min, Max, Min&Max |

| Coupling loss alarm | ✔ |

| Last reading (in coupling loss) | ✔ |

| A-Scan | ✔ |

| Cursor (Detect Line) | ✔ |

| Thickness B-Scan | ✔ |

| Thickness C-Scan | ✔ |

| Multidimensional files: Browsing | ✔ |

| Multidimensional files: File Statistics | ✔ |

| Multidimensional files Meas. Site Statistics | ✔ |

| Calibration | |

| 1-point | ✔ |

| 2-points | ✔ |

| Zeroing in the air | ✔ |

| Zeroing on a built-in block | ✔ |

| Memory | |

| Setups | ✔ |

| Multidimensional structured files | 1-3 dim |

| Number of readings per file | Up to 100 000 |

| Number of files format | 6 |

| Data attachments | Comments, A-Scans, Thickness B-Scans, Thickness C-Scans, Microgrids |

| Capacity | 2 GB (up to 64 GB) |

| PC software | ✔ |

| Other Features | |

| Keyboard backlight | ✔ |

| Smart (Context) keyboard backlight | ✔ |

| Smart zoom | ✔ |

| Number of keyboard shortcuts2 | 29 |

Instructional Video

Introduction to Training

Part 1 Interface Concept

Part 2 Menu types

Part 3 Main functions

Part 4 Probe and test object parameters calibration

Part 5 DAC Calibration