SKOOT • X

SKOOT • X

Every radiography inspection is unique, from the type of detector and source to be used to the size and material of the pipe. The innovative SKOOT • X can meet the needs demanded of any application. The handheld controller allows for remote operation and the programming of specific scan patterns around the sample. Mount your choice of detector and source with the ability to adjust the receiving detector's angle, rotation, height and more to achieve precision results. The powerful SKOOT • X crawler can carry sources up to 29 kg (65 lb), and the built-in encoder tracks the exact position of a scan for repeatable results. Quick-release chain links provide a fantastic method of attaching the SKOOT • X system to ferrous and non-ferrous materials. These same chain links can be sized to fit pipes from 20.3 cm (8 in) to 106.7 cm (42 in). Order the SKOOT • X to match your instruments and discover the ease of automated radiography inspection.

Part ID: EBG001-42-30-E-07

Precision automated digital radiography inspection made possible.

FEATURES

AUTOMATED CONTROL

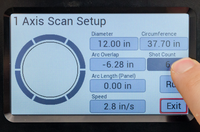

The built-in software allows users to program specific scan patterns around a pipe. Input the pipe diameter and how many photographs to capture, and the software will calculate the intervals necessary. Speed and other variables are also available to customize your inspection as required.

NON-FERROUS INSPECTION

Perform radiography inspection on magnetic and non-magnetic surfaces using the adaptable chain system. The chain links are assembled around the circumference of the pipe, 'clamping' the system to the pipe.

SCAN VERSATILITY

Circumferential operation is possible on pipes as small as 20.3 cm (8 in) and as large as 106.7 cm (42 in) OD. An adjustable buckle permits the user to adjust the chain tension as required.

REMOTE CONTROL

Manage crawler operations with the rugged handheld controller, featuring joysticks, a large colour touch screen and haptic feedback. Inspectors can control the system remotely from up to 6 ft away Magnets on the rear of the controller to prevent drops

ADJUSTABILITY

Mount the detector bracket to the crawler for seemingly infinite adaptability to angle the detector as required.

COMPATIBILITY

Pair the SKOOT • X with any number of radiographic instruments and manufacturers. Contact us to develop custom brackets to fit your particular detector.

CABLE MANAGEMENT

Protective cable management is provided to shield any cables from damage and to keep them organized.

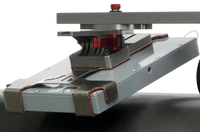

SOURCE CART

The source cart holds the user's source. The mounting plate attaches directly to the source and is removable from the source cart using the quick-release red handle. This allows the SKOOT • X system to set up on a pipe first before lifting a heavy source and attaching it to the quick-release of the source cart. (mounting plate not shown in image)

MAGNETIC INSPECTION

Designed to be highly adaptable and adjustable, the SKOOT • X may also be ordered with magnetic wheels for carrying a detector around ferrous pipes and surfaces.

Contact our technical sales specialists to order the SKOOT • X with magnetic wheels.

BATTERY POWER

Order the SKOOT with the battery kit and avoid using heavy, cumbersome generators. These rechargeable batteries can power the SKOOT system and accessories for hours.

WARRANTY

Engineered and designed to perform flawlessly. We back our products for three years.

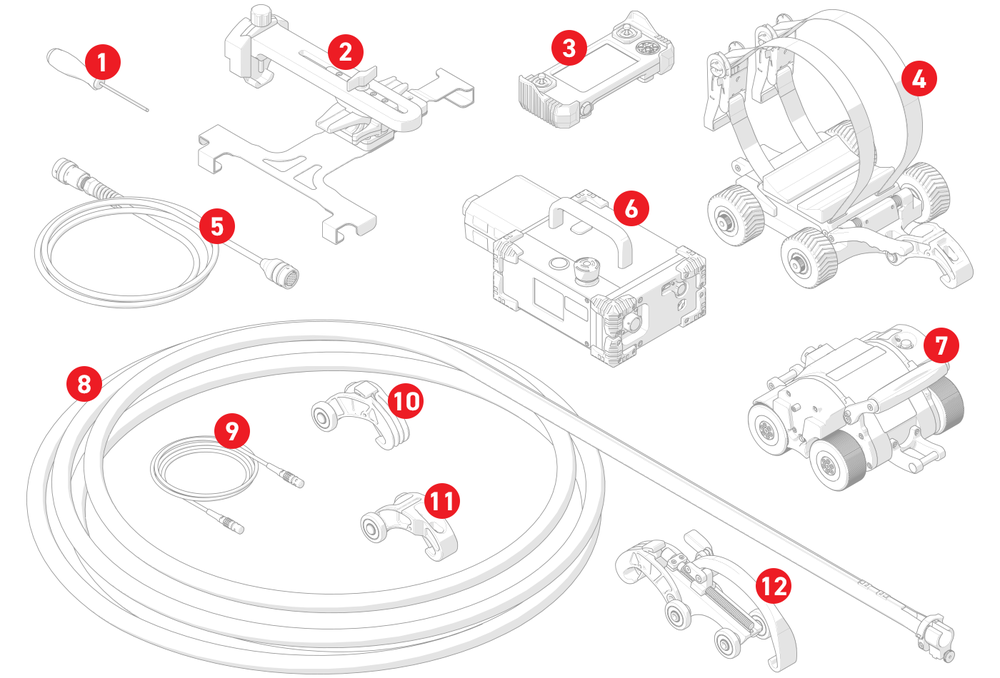

COMPONENT IDENTIFICATION

3 MM HEX DRIVER

The 3 mm hex driver is suitable for most SKOOT • X adjustments.

DETECTOR BRACKET

Various detector brackets are available and compatible with the detector of your choice. The detector bracket features height, rotation and angle adjustments to capture images as required.

HANDHELD CONTROLLER

The handheld controller contains the SKOOT • X operating system. Users can set scan parameters using the intuitive touchscreen.

SOURCE CART

The source cart attaches to the chain links of the system and carries the source device.

UMBILICAL

The backbone of communication between the power controller and the crawler.

POWER CONTROLLER

Compatible with North American, European and UK power sources, the power controller utilizes various power sources to provide crawler power.

SKOOT • X CRAWLER

The powerful crawler moves the system circumferentially around the pipe. The SKOOT • X crawler also includes a convenient handle, and the detector bracket mounts on the side of the crawler.

CABLE MANAGEMENT

Protect and organize cables with rugged cable management sleeving.

AUXILIARY CABLE

This cable connects the handheld controller to the power controller.

CHAIN LINK

Quick-release links assemble a chain system holding the scanner on the inspection surface.

DOVETAIL LINK

This link provides an attachment point for accessories such as cable management.

BUCKLE

The buckle completes the chain system around a pipe and adjusts the chain tension when required.

SPECIFICATIONS

GENERAL

Encoder Resolution: 220.4 counts/mm (5,598.4 counts/inch)

Maximum Source Payload: 29 kg (65 lb)

Maximum Speed: 7.4 cm/sec (2.9 in/sec)

Power Requirements: 100-240VAC, 50/60Hz, 1.4 Amps

Maximum Umbilical Length: 30 m (98.4 ft)

Inspection Surface: Ferrous and non-ferrous

PIPE RANGE

Circumferential, Outer Diameter (OD): 20.3 cm (8 in) to 106.7 cm (42 in)

REGULATIONS

CE: European Union CE Declaration – Compliance with essential requirements and provisions of European Union directives.1

FCC: Compliance with Part 15 of FCC rules.1

Industry Canada: CAN ICES-3 (A)/NMB-3(A) – This class A digital apparatus complies with Canadian ICES-003.1

UKCA: United Kingdom Conformity Assessed – Compliance with relevant UK statutory requirements and legislation.1

SIZE & WEIGHT

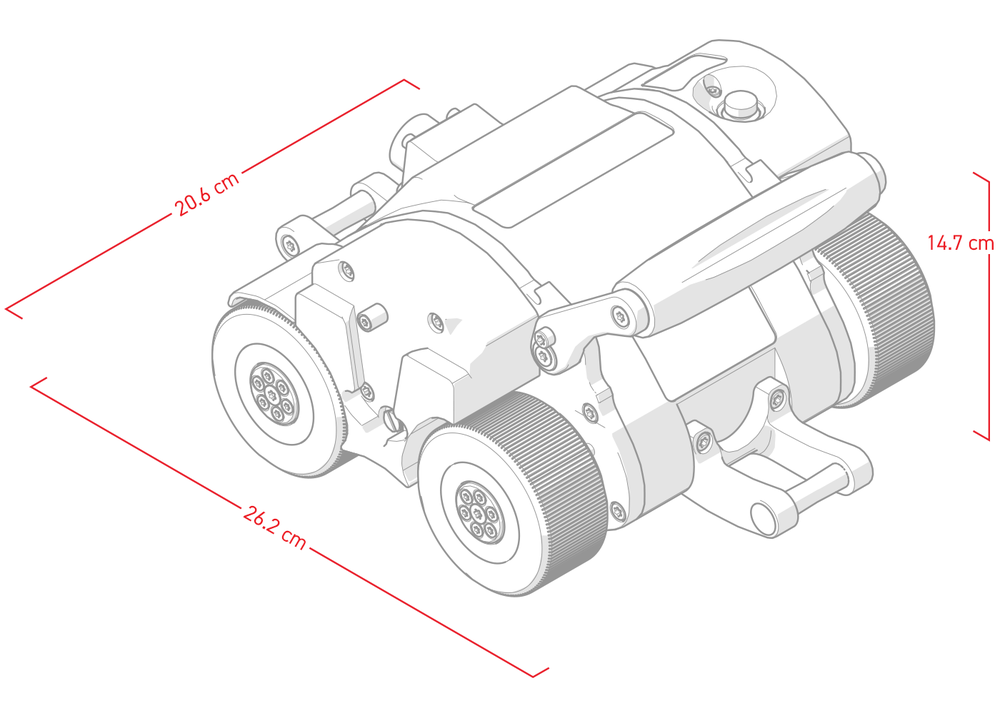

Base Crawler Width: 20.6 cm (8.1 in)

Base Crawler Depth: 26.2 cm (10.3 in)

Base Crawler Height: 14.7 cm (5.8 in)

Base Crawler Weight: 4.6 kg (10.1 lb)

ENVIRONMENTAL SPECIFICATIONS

Operating Environment: -20°C (-4°F) to 50°C (122°F)

Environmental Sealing: Dust-tight, watertight (not submersible)

DETECTOR BRACKETS

01

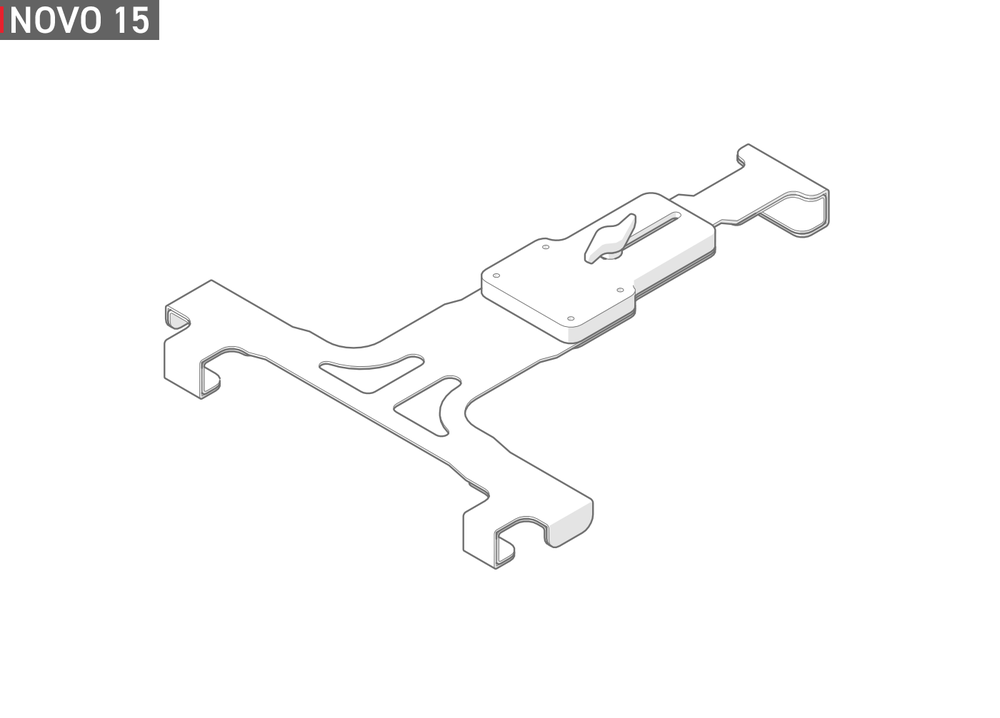

NOVO 15

02

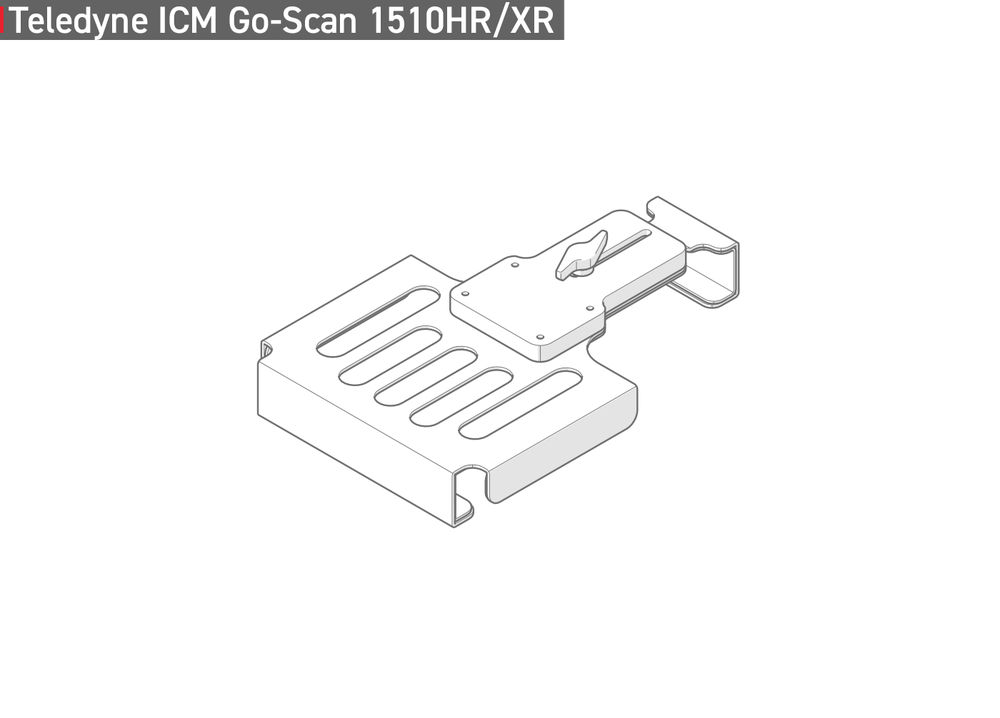

Teledyne ICM Go-Scan 1510HR/XR

03

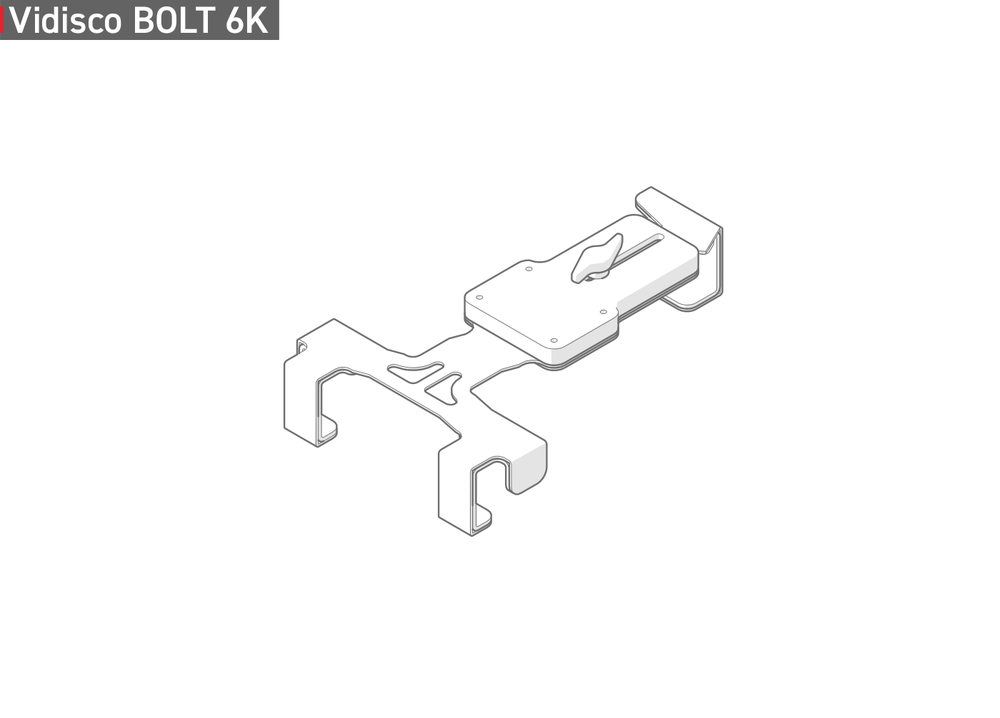

Vidisco BOLT 6K

04

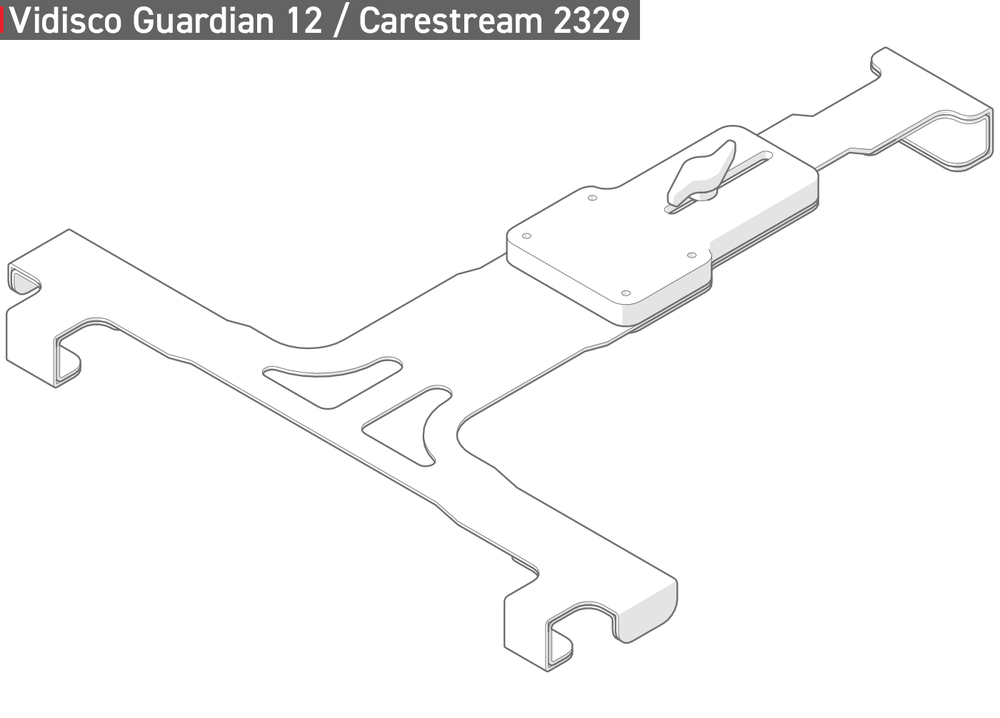

Vidisco Guardian 12

Carestream 2329

05

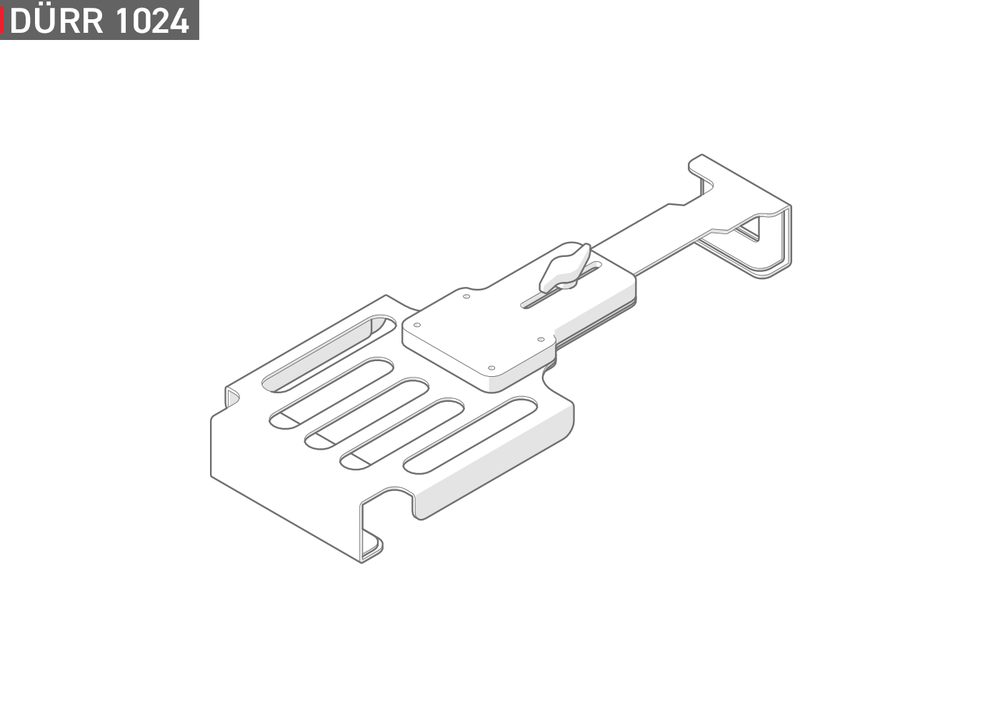

DÜRR 1024

06

Carestream HPX-DR 3543

07

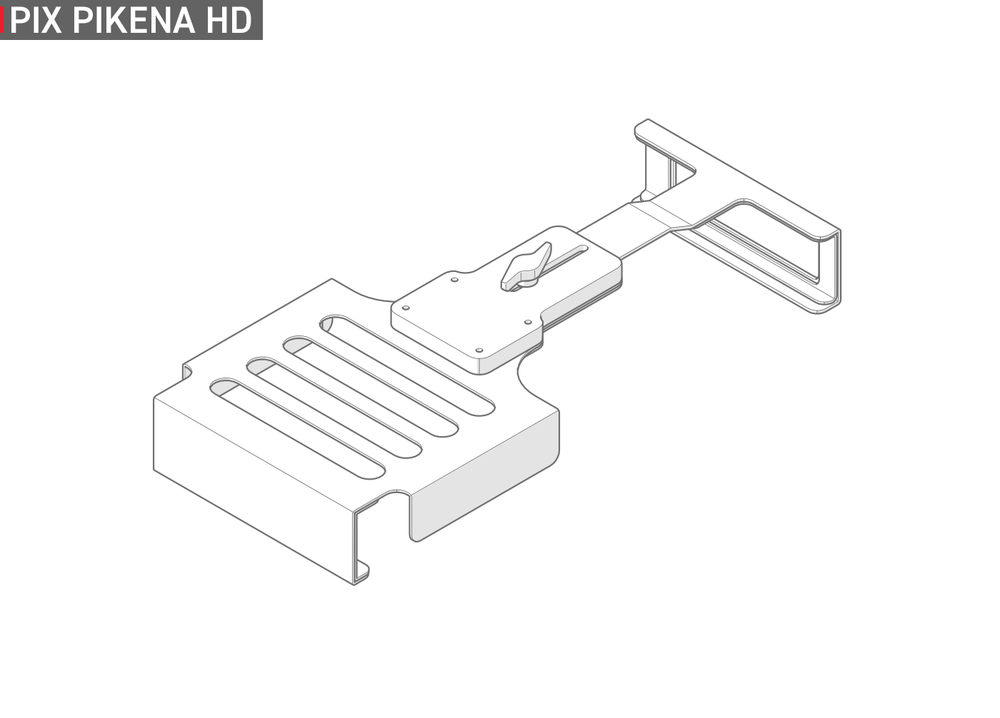

PiX Pikena HD

POWER CORDS

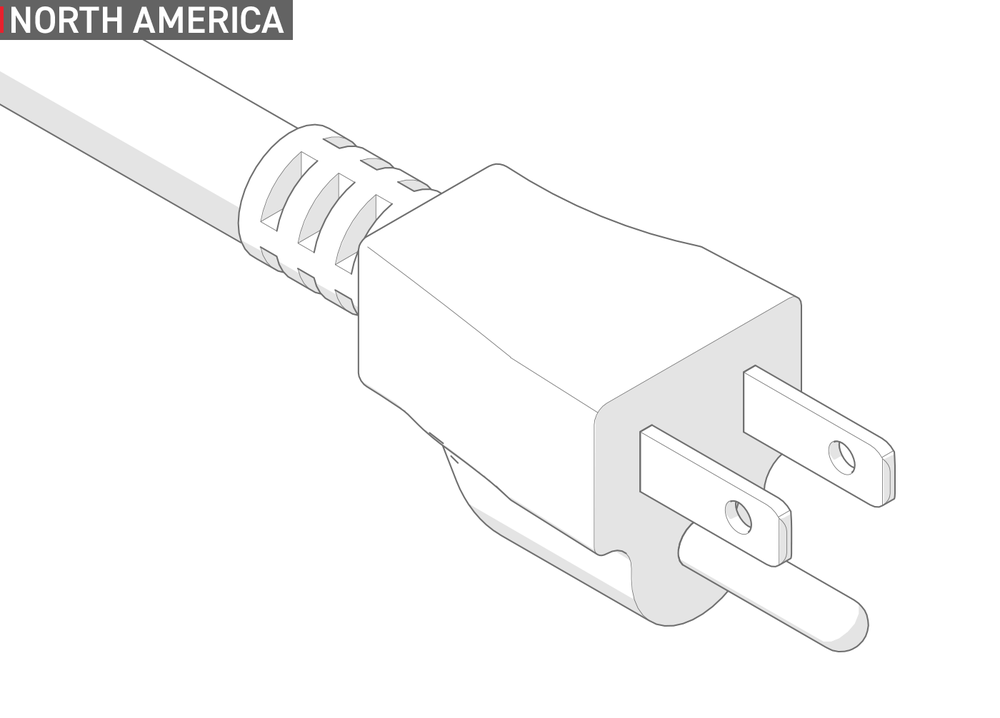

POWER REQUIREMENTS

100-240VAC, 50/60Hz, 3.5 Amps

PLUG DESIGNATION

North America

NEMA 5-15P

Europe

CEE7/7

UK

BS1363A