SKOOT - Corrosion Mapping Scanner

SKOOT - Corrosion Mapping Scanner

The automated SKOOT - Corrosion Mapping Scanner is a powerful scanner that can perform complex corrosion inspections while traversing all magnetic surfaces. Remote operation combined with one of any four lengths of motorized raster arm ensures the SKOOT is the leader of automated two-axis corrosion scans.

Perform complex corrosion inspection using any number of accessories.

FEATURES

LOW PROFILE

The SKOOT requires a radial clearance of 11.4 cm (4.5 in), which allows for inspection in limited-access applications.

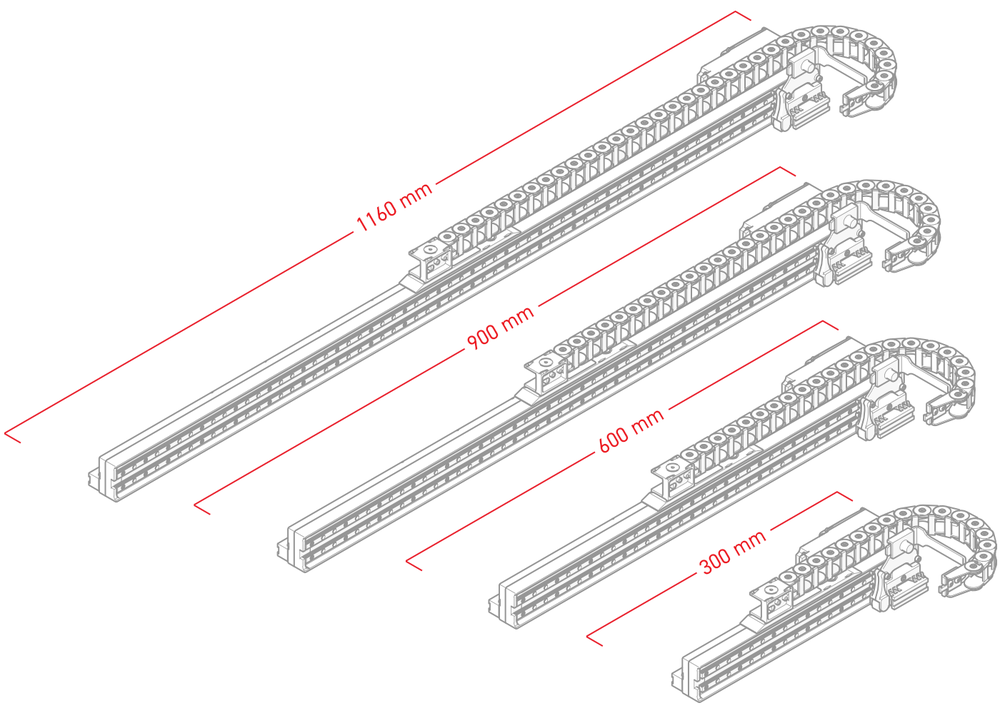

RASTER ARMS

Available in 4 different lengths, the sophisticated raster arm delivers precision corrosion results: program custom scan paths, intervals, speed and more for repeatable and highly configurable readings.

MAGNETIC WHEELS

The SKOOT can operate on vertical, horizontal and inverted surfaces using rare-earth magnetic wheels.

SCAN VERSATILITY

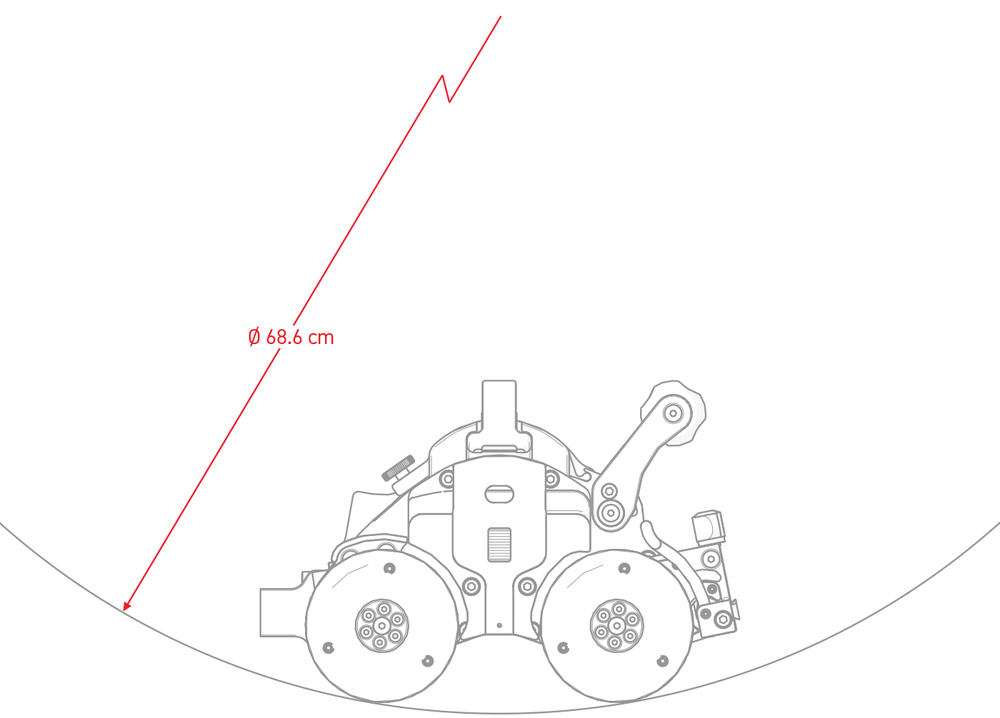

The SKOOT can facilitate circumferential scans on pipes as small as 6.4 cm (2.5 in) OD and 68.6 cm (27 in) ID. In addition, flat surface scans and longitudinal scanning on pipes as small as 76.2 cm (30 in) OD are available.

BACKPACK

The optional backpack conveniently carries ultrasonic accessories with the unit.

HANDHELD CONTROLLER

Program raster paths from up to 30 m (100 ft) away using the intuitive handheld remote control. The ergonomic handheld controller programs probe speed, intervals, and much more.

BATTERY POWER

Order the SKOOT with the battery kit and avoid using heavy, cumbersome generators. These rechargeable batteries can power the SKOOT system and accessories for hours at a time.

WARRANTY

A 3-year warranty backs all components of the SKOOT system.

KIT CONTENTS

SCANNER

SKOOT base crawler

PARTS & ACCESSORIES

Power controller

Power supply (North American, European or UK plugs available)

Umbilical, 7.5 m (25 ft) or 30 m (100 ft) lengths available

Handheld controller

Auxiliary cable, 6 m (20 ft)

Manipulation handle

Cable management, threaded mount, (length dependent on umbilical length)

J300 encoder cable, 5 m (15 ft)

Installation/Removal mat

6 mm ID irrigation kit (7/16 in quick connect)

Lifting sling (safety tether)

User manual

Rugged carrying cases (various types based on chosen accessories)

TOOLS

3 mm hex driver

3 mm flat driver

Wrench for pivot button adjustment

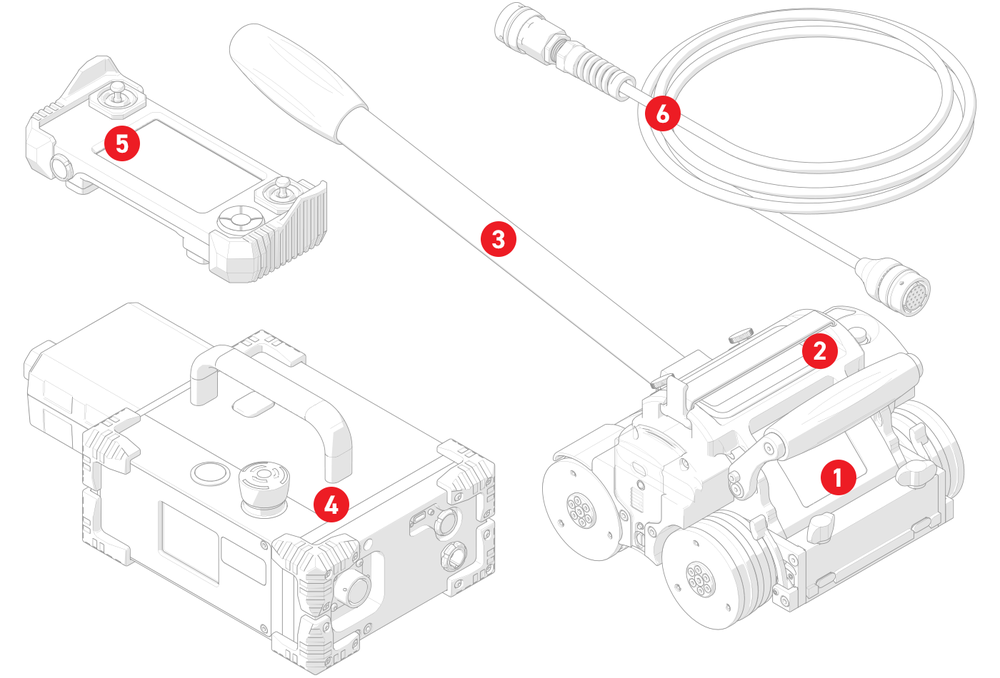

COMPONENT IDENTIFICATION

BASE CRAWLER

Four highly magnetic wheels propel the SKOOT crawler along ferrous surfaces. Attach many weld and corrosion scanning accessories to the crawler, which features cable management and an integrated encoder.

BACKPACK

A flexible strap securely holds any pre-amp, splitters or scan accessories to the SKOOT crawler.

MANIPULATION HANDLE

Slight steering adjustments and crawler manipulation are achieved using the manipulation handle.

POWER CONTROLLER

Configurable for North American or European electrical standards, the power controller is a sophisticated operating platform and connection point for instrumentation and handheld controllers.

HANDHELD CONTROLLER

Precision forward and reverse drive control, programmable y-axis control, and system diagnostics are all accessed using the handheld controller's touchscreen and joysticks.

UMBILICAL

The backbone of communication between the power controller and the base crawler.

SPECIFICATION

GENERAL

Encoder Resolution: 1354 counts/mm (34394 counts/inch)

Maximum Vertical Payload: 9 kg (20 lb)1

Maximum Speed: 14.2 cm/sec (5.6 in/sec)

Power Requirements: 100-240VAC, 50/60Hz, 1.4 Amps

Umbilical Length: 7.5 m (25 ft)2

Inspection Surface: Ferrous

Maximum Backpack Payload: 1.36 kg (3 lb)

PIPE RANGE

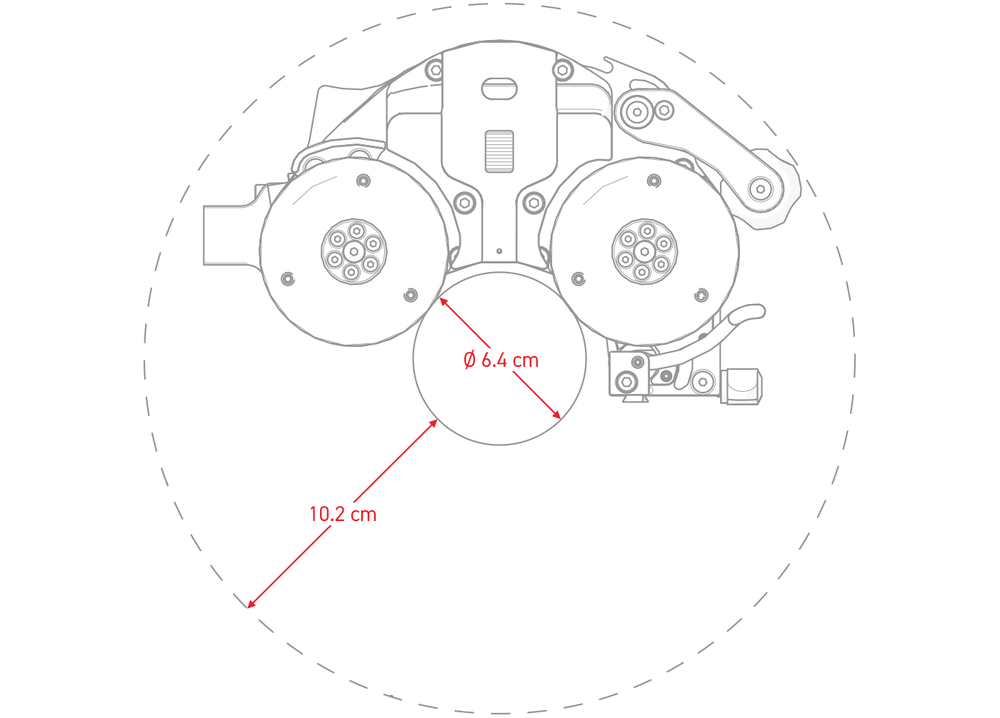

Circumferential, Outer Diameter (OD): 6.4 cm (2.5 in) to flat

Circumferential, Inner Diameter (ID): 68.6 cm (27 in) to flat

Longitudinal: 76.2 cm (30 in) to flat

RADIAL CLEARANCE

Pipes under 200 mm (8 in): 10.2 cm (4 in)3

Pipes over 200 mm (8 in): 11 cm (4.3 in)3

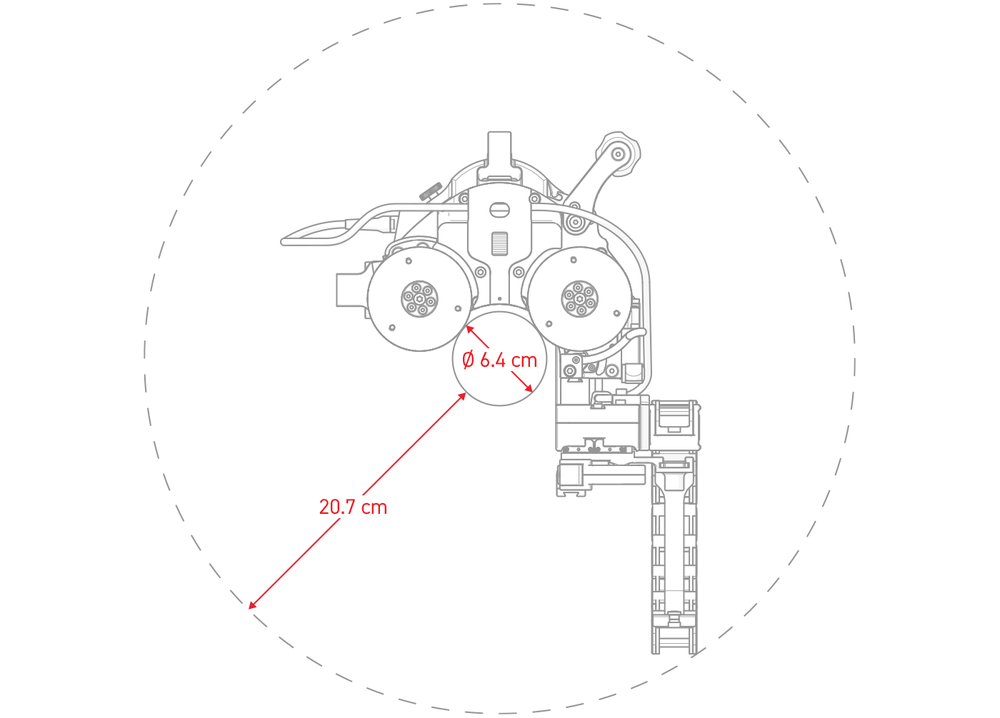

With Motorized Raster Arm and Cable Tray: 20.7 cm (8.1 in)

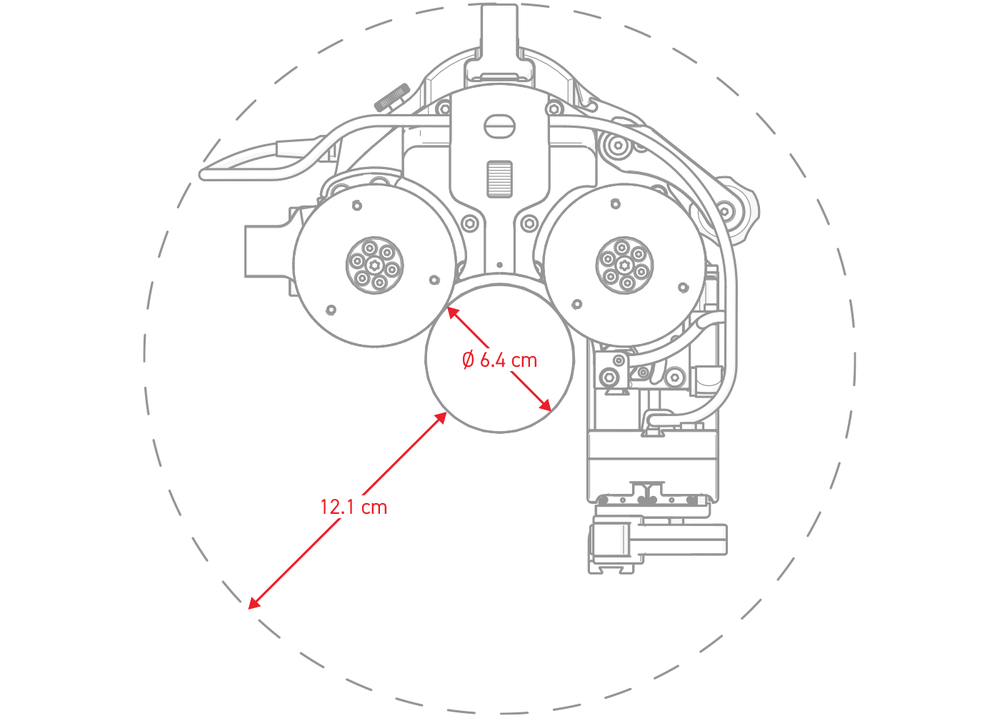

With Motorized Raster Arm: 12.1 cm (4.8 in)

REGULATIONS

CE: European Union CE Declaration – Compliance with essential requirements and provisions of European Union directives.4

FCC: Compliance with Part 15 of FCC rules.4

Industry Canada: CAN ICES-3 (A)/NMB-3(A) – This class A digital apparatus complies with Canadian ICES-003.4

UKCA: United Kingdom Conformity Assessed – Compliance with relevant UK statutory requirements and legislation.4

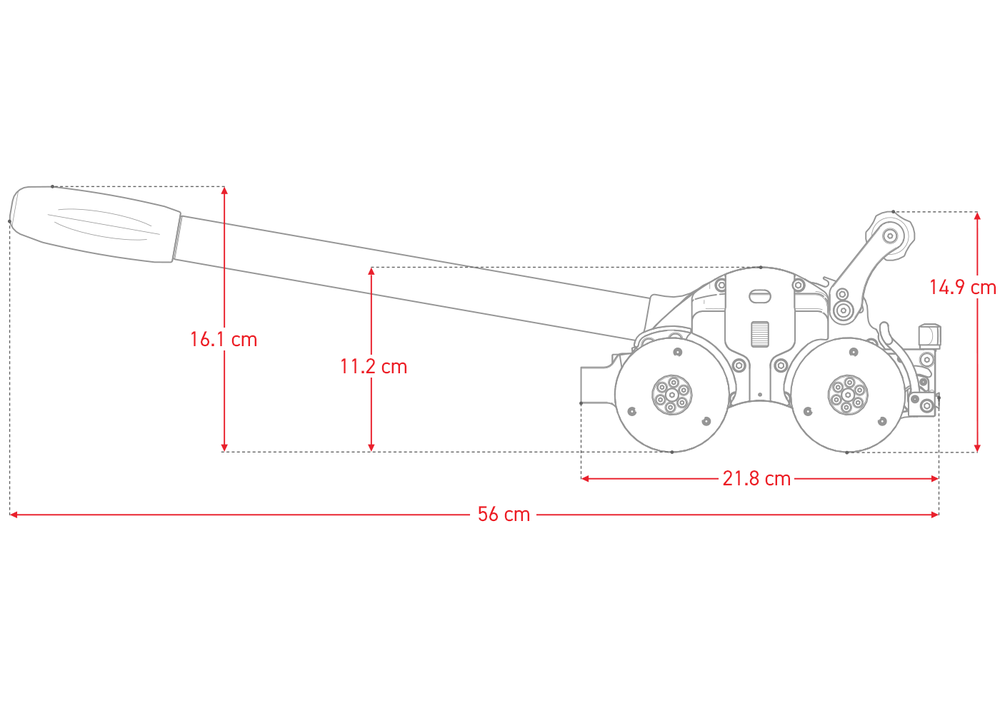

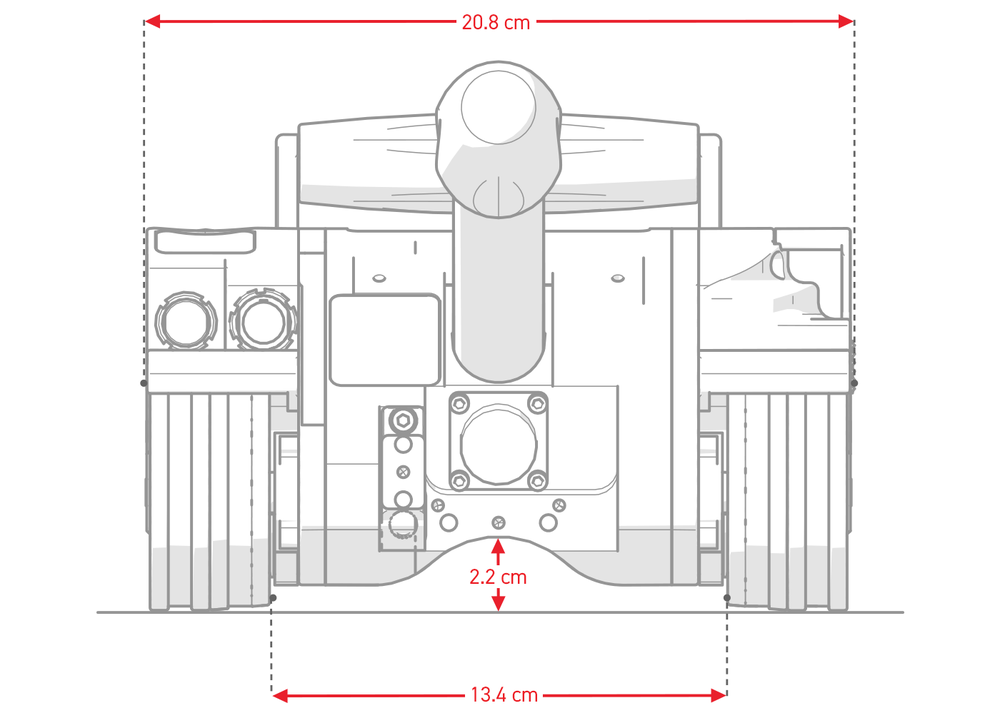

SIZE & WEIGHT

Base Crawler Height: 11.2 cm (4.4 in)5

Base Crawler Height, including handle: 14.9 cm (5.9 in)

Base Crawler Height with manipulation handle: 16.1 cm (6.3 in)

Base Crawler Width: 20.8 cm (8.2 in)

Base Crawler Length: 21.8 cm (8.6 in)

Base Crawler Length with manipulation handle: 56 cm (22 in)

Base Crawler Weight: 7.3 kg (16 lb)

ENVIRONMENTAL SPECIFICATIONS

Operating Environment: -20°C (-4°F) to 50°C (122°F)

Environmental Sealing: Dust-tight, watertight (not submersible)

Maximum Inspection Surface Temperature: 150°C (302°F)6

RASTER ARM SPECIFICATIONS

Raster Arm Module Encoder: 240.2 counts/mm (6100.9 counts/inch)

Raster Arm Module Speed: 0 - 76.2 cm/sec (0 - 30 in/sec)

RASTER ARM WEIGHT

300 mm Raster Arm (12 in): 2.45 kg (5.4 lb)

600 mm Raster Arm (24 in): 3.36 kg (7.4 lb)

900 mm Raster Arm (35 in): 4.04 kg (8.9 lb)

1160 mm Raster Arm (45 in): 4.54 kg (10 lb)

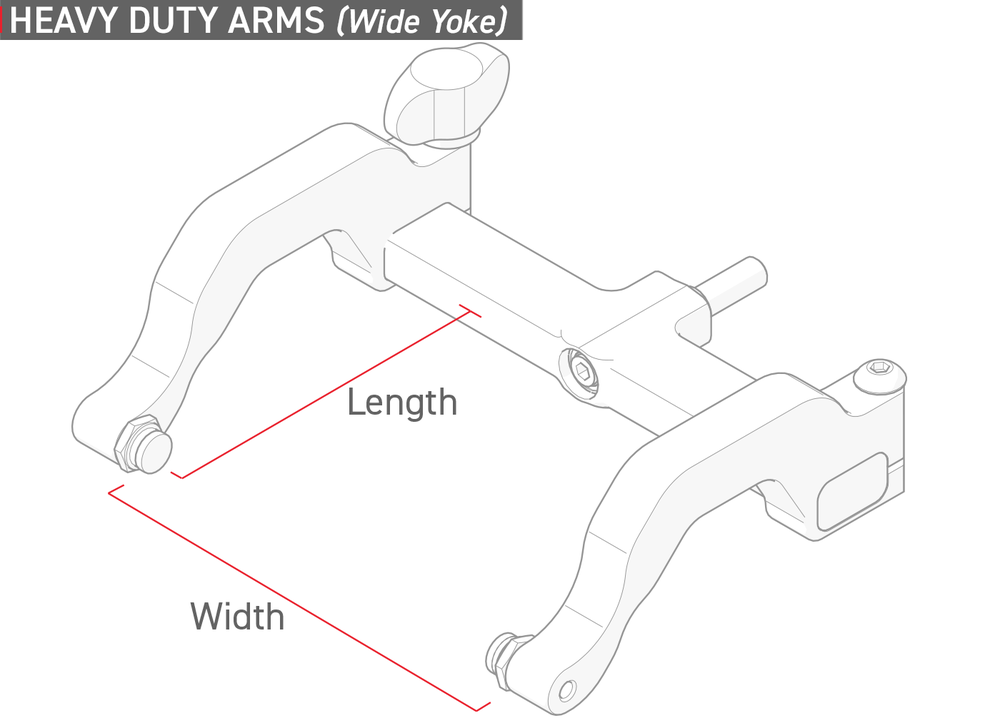

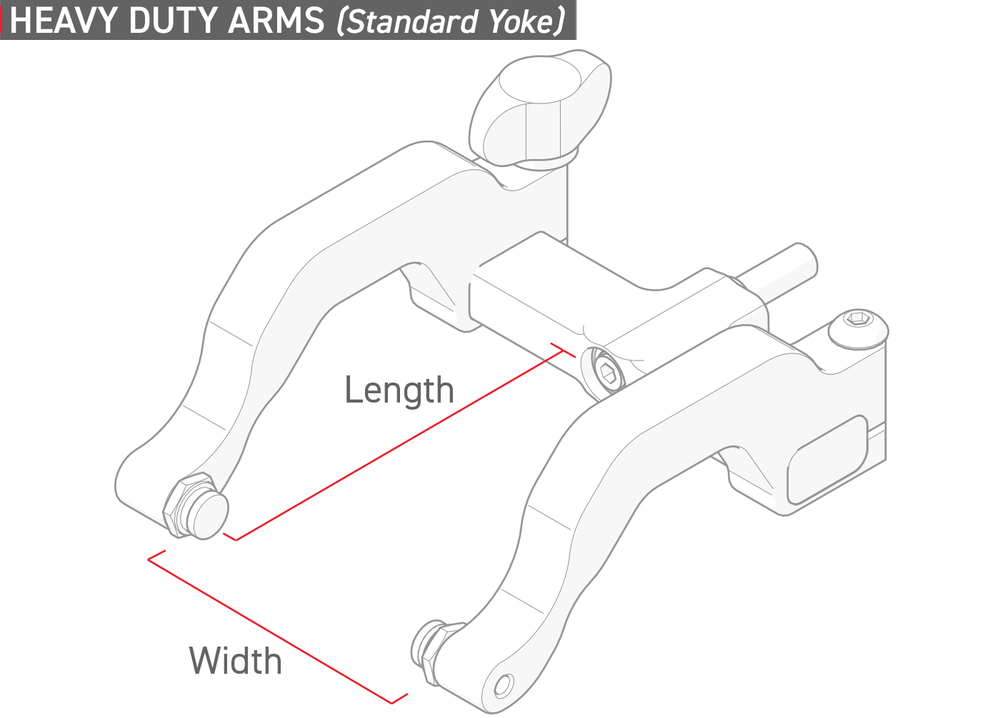

HEAVY DUTY VERTICAL PROBE HOLDER SPECIFICATIONS

Standard Width: 17.4 mm (0.69 in) – 55 mm (2.17 in)

Standard Length: 63.5 mm (2.5 in)

Wide Width: 17.4 mm (0.69 in) – 93.8 mm (3.69 in)

Wide Length: 63.5 mm (2.5 in)

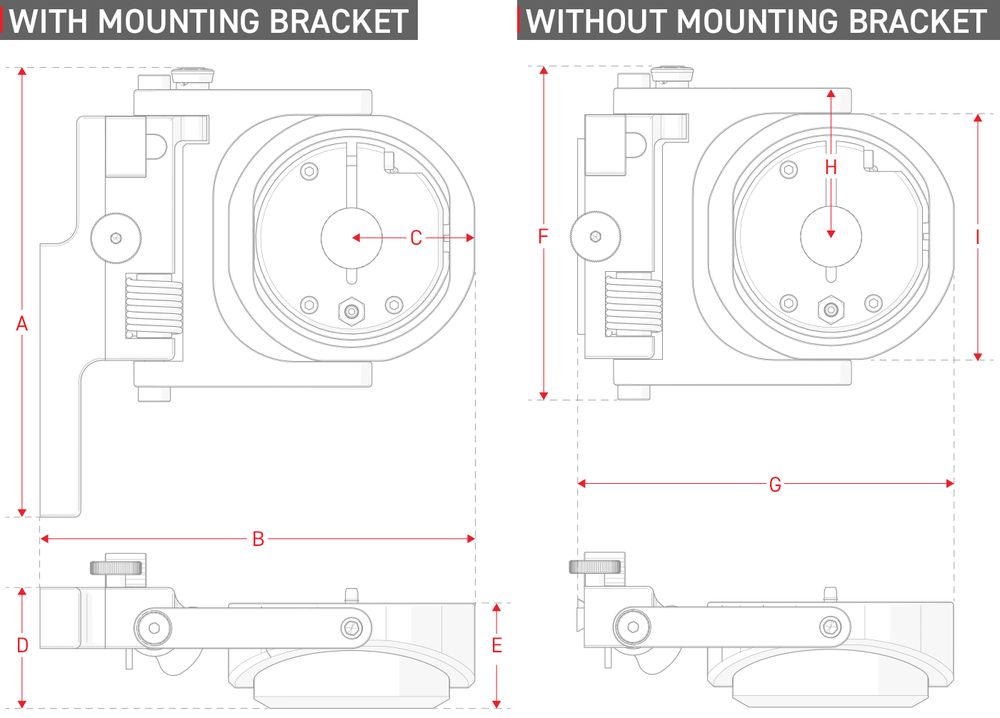

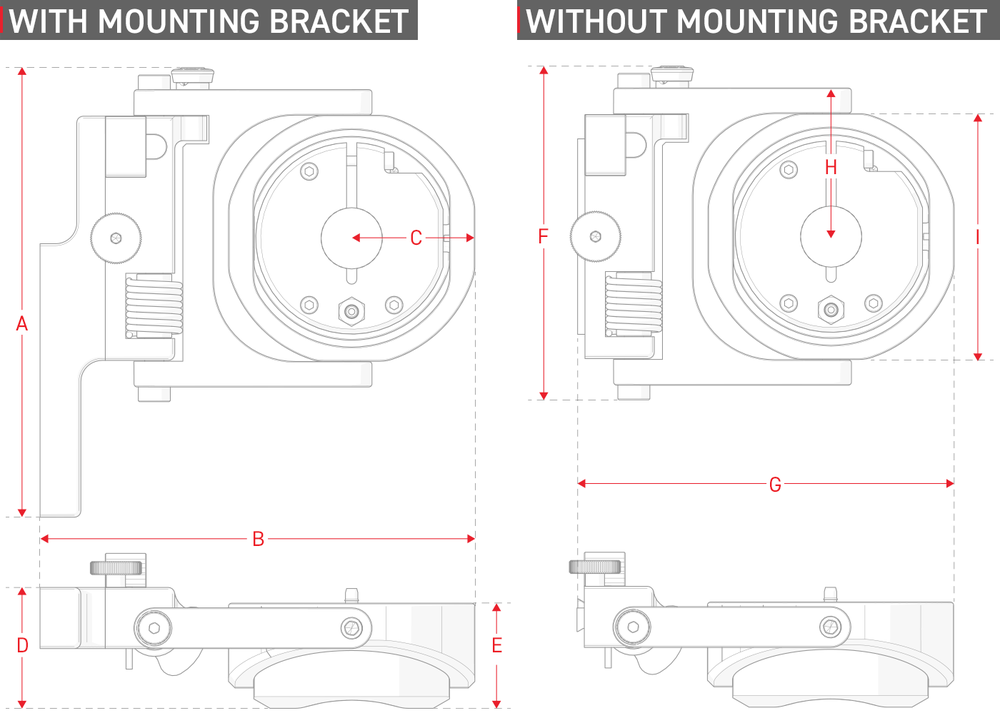

CORROSION THICKNESS PROBE HOLDER SPECIFICATIONS

SIZE AND WEIGHT

With Mounting Bracket

A - 140.09 mm (5.52 in)

B - 135.18 mm (5.32 in)

C - 38.28 mm (1.51 in)

D - 38.28 mm (1.51 in)

Weight: 0.5 kg (1.1 lb)

Without Mounting Bracket (Raster Arm Application)

E - 32.77 mm (1.29 in)

F - 104.08 mm (4.10 in)

G - 117.27 mm (4.62 in)

H - 46.33 mm (1.82 in)

I - 76.66 mm (3.02 in)

Weight: 0.4 kg (0.9 lb)

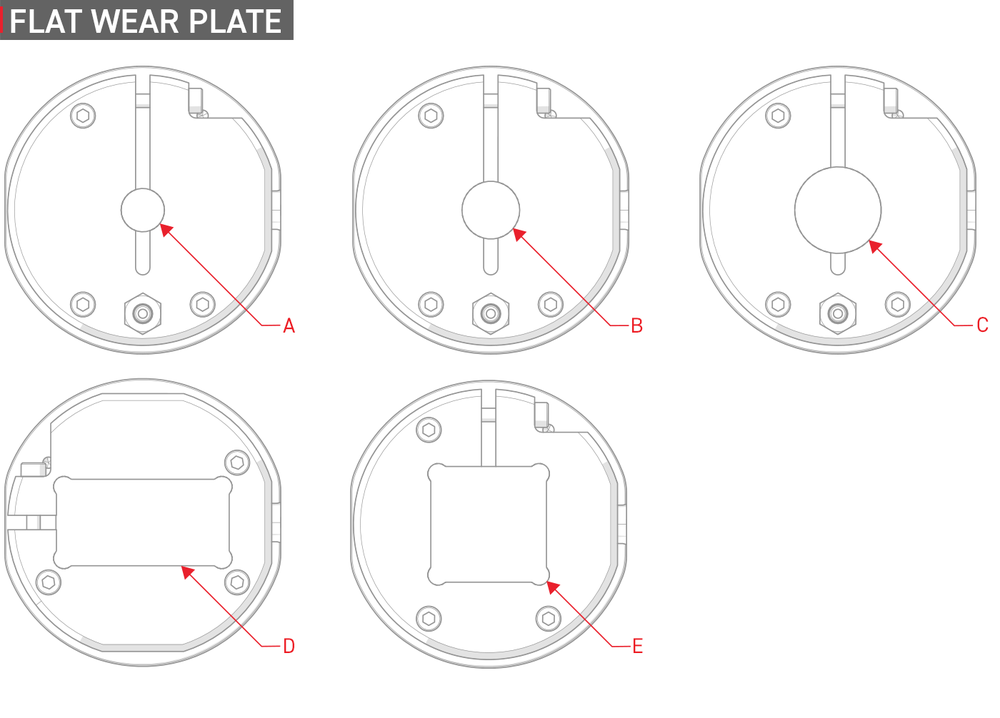

RECEPTACLE SIZES

Flat Wear Plate

A - 9.53 mm (0.375 in) dia.

B - 12.7 mm (0.5 in) dia.

C - 19 mm (0.75 in) dia.

D - Technisonic

E - 25.4 mm (1 in)

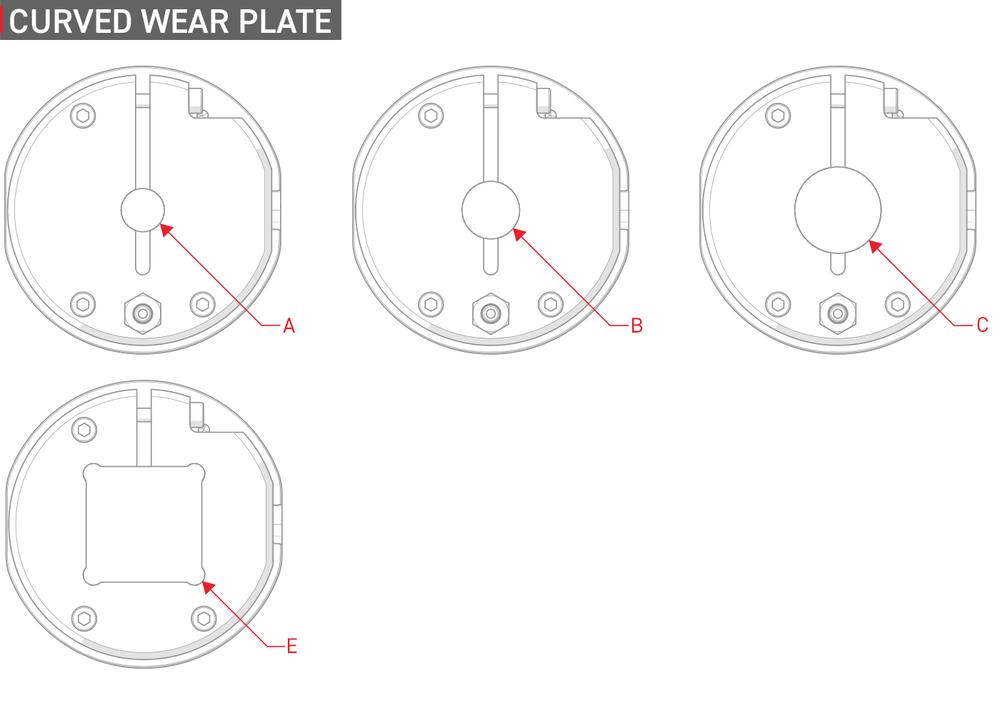

Curved Wear Plate

A - 9.53 mm (0.375 in) dia.

B - 12.7 mm (0.5 in) dia.

C - 19 mm (0.75 in) dia.

E - 25.4 mm (1 in)